Tube Cutting Machine

About The Product

Precision cutting is achievable with the advanced technology of this fiber laser tube cutting machine. The high-speed operation ensures efficient processing of various tube materials. This machine offers exceptional accuracy and clean cuts, minimizing material waste. Its automated features streamline production for increased productivity. It Can Cut Different Shape Such as BAR, SQUARE, RECTANGLE, H-BEAM, I-BEAM Etc. All in one machine.

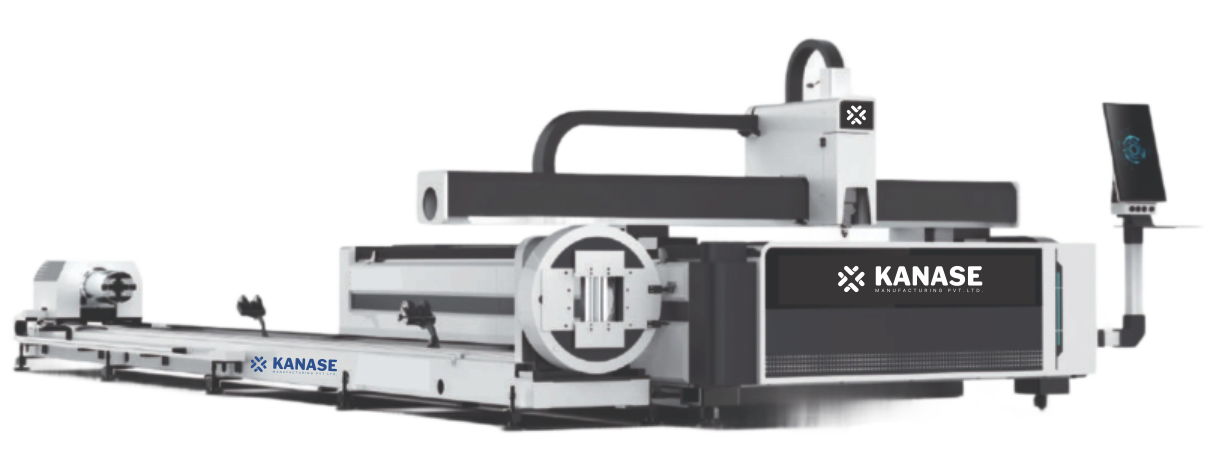

Sheet & Tube Cutting Machine

About The Product

Precision sheet and tube laser cutting offers unparalleled accuracy for intricate designs. This advanced technology seamlessly cuts various materials with speed and efficiency. The versatility of these machines allows for a wide range of applications across diverse industries. From prototyping to high-volume production, laser cutting delivers exceptional results. Explore the possibilities of transforming your designs into reality with this cutting-edge technology. It can cut sheet as well as round tube, Bar, H-beam, I-beam, versatile machine for sheet and pipe cutting.

Technical Specification

| Source | Category |

|---|---|

| Range of Tube Diameter | Round Tube: Ø10mm-Ø120mm / Ø20mm-Ø220mm |

| the Maximum Tube | Rectangular: Ø10mm-Ø120mm / Ø20mm-Ø220mm |

| Length | 6000 mm |

| Power | 1500-3000W |

| Transmission System | Rack and Pinyon, Servo Drive |

| Loading System | Semi-Auto / Full-Auto (Optional) |

| Loading Time (from The Second Tube) | 15S-20S (Time Of Waiting Loading) |

| The Max Acceleration | 1.2G |

| The Max Speed | 100 RPM/min |

| Positioning Accuracy | ±0.05mm/1000mm |

| Length of Scraps | ≥30 mm |

| Minimum Length of Front Shock Avoidance | ≥450 mm |

| Jaw Clamping Weight | 120chuck: 110 Kg. |

| Graphic Format | IGS., etc. |

| Working Environment | 0-45, Humidity≤ 80%, No Freezing |

| Equipment Power | 12 KW (Resonator Not Included) |

| Voltage Supply | 3 Phase 380V / 50Hz / 60Hz |

| Net Weight | 3600 Kg. |

| Dimension | 10200mm x 2350mm x 2200mm |

Features

- The Focus Is Controlled by an Internal Precision Motor and Does Not Require Manual Operation.

- Optimized Optical Configuration and Smooth and Efficient Airflow Design Significantly Improve Cutting Quality and Efficiency.

- Modular Design and The Design of Fine Nozzles Effectively Avoid Work Piece Interference When Cutting Special Pipes.

Application

- Round Tube

- Rectangle Tube

- U Type Tube

- Channel Steel

- I Beam.